As electronics get smaller and more powerful, managing heat is more important than ever. Whether you’re building a new gadget or fixing up an old one, the right heat sink can mean the difference between top performance and failure. But how do you pick the best heat sink for your project?

Try our free heat sink calculator! It makes thermal management easy for engineers, hobbyists, and DIYers. No more guessing—just precise, smart cooling. Let’s get started and keep your projects running cool!

What Is a Heat Sink Calculator?

A heat sink calculator is an online tool or software that helps engineers, designers, and hobbyists estimate the size and specifications of a heat sink needed to effectively cool an electronic component or device. It simplifies the complex calculations involved in thermal management by considering various factors such as:

- The amount of heat generated by the component (power dissipation in watts).

- The maximum allowable temperature for the device.

- The ambient temperature around the heat sink.

- The thermal resistance of the heat sink material.

- Airflow conditions (natural or forced convection).

When you enter these values, the calculator helps you figure out the right heat sink size, type, or thermal resistance needed to keep your device cool and safe. This makes it easier to pick or design the best heat sink for good cooling.

Why Use a Free Heat Sink Calculator?

Free heat sink calculators are super helpful for engineers, designers, and hobbyists working to keep electronics cool. Here’s why they’re so useful:

Save Money

They let you estimate how well a heat sink will work without spending money on expensive software or needing special training. Great for small projects or tight budgets.

Design Faster

You can quickly test different materials, fin sizes, and airflow options. This speeds up your work and helps you find the best design without doing complicated math by hand.

Get More Accurate Results

Enter details like power and temperatures for more accurate heat sink performance predictions, leading to smarter, more reliable cooling choices.

Learn and Teach Easily

These calculators simplify learning and teaching thermal management by showing how different factors impact cooling.

Choose the Best Materials and Designs

Compare materials and designs, like aluminum vs. copper and shapes, to find the best fit for your needs.

Work With Different Cooling Methods

Many calculators handle both natural airflow and fan-driven cooling, so you can design heat sinks for different environments.

Free heat sink calculators save you time and money, give accurate results, help you learn, and make designing better cooling systems easier. They’re great tools for anyone working with thermal management.

How the Calculator Works

1. What You Enter (Input):

You provide details about the heat sink and the component it’s cooling, such as:

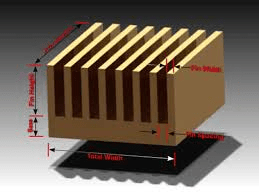

- Heat sink type (flat or pin fin), material (aluminum or copper), size, and fin design.

- Heat source size, how much heat it produces (in watts), and the surrounding air temperature.

- Information about the thermal interface material (like thermal paste or pads), including its type, thickness, and how well it conducts heat.

2. What It Calculates:

Using your inputs, the calculator figures out important heat-related values, including:

- The total surface area of the fins affects how well heat is released.

- How well the heat sink material conducts heat.

- Thermal resistance shows how easily heat passes through the heat sink (lower resistance means better cooling).

Temperatures are measured at the heat sink base, overall heat sink, and CPU junction.

These results help determine if the heat sink will keep your device cool enough during operation.

3. What You Get (Output and Suggestions):

The calculator shows:

Thermal resistance value.

Expected temperatures at the heat sink and CPU.

Things to Keep in Mind

The calculator uses a mathematical model that may not cover every real-world detail.

The calculator works well for most designs, but if your project is unusual or outside its range, it’s a good idea to get advice from experts.

Testing the design in real life is important to make sure it performs as expected.

The Heat Sink Calculator helps you quickly estimate and choose the right heat sink to keep your electronics running safely and efficiently.

Tips for Better Thermal Design

Plan for Heat Early: Think about how heat will be managed right from the start of your design to avoid expensive changes later and keep your product working well.

Place Components Smartly: Keep high-heat parts away from sensitive areas. Use features like thermal vias and copper layers on the circuit board to help spread and remove heat.

Choose the Right Materials: Use materials that conduct heat well, like metal-core circuit boards (such as aluminum-backed ones) for high-power devices, or better-quality FR-4 for regular uses.

Improve Airflow: Design the device’s case or enclosure so air flows smoothly, helping carry heat away. Add fans or vents if needed for better cooling.

Use Thermal Interface Materials (TIMs): Place materials like thermal paste or pads between hot components and the heat sink to reduce resistance and help heat move away faster.

Use Simulation Tools: Run thermal simulations on your design to spot hot spots and fix problems before making physical prototypes.

Try Advanced Cooling Methods: Consider advanced solutions like two-phase cooling systems for even better heat removal when needed.

By following these tips, your electronic designs will run cooler, perform better, and last longer.

Common Mistakes to Avoid

Guessing Power and Temperature

Mistake: Estimating how much heat (power) a component produces or the surrounding temperature without accurate data.

Why it matters: Wrong guesses can make your heat sink too small (causing overheating) or too big (wasting space and money).

Best tip: Measure carefully or use calculations and simulations. For example, calculate power with: Power (P) = Current (I) × Voltage (V).

Ignoring Airflow Direction and Type

Mistake: Not considering how air moves around the heat sink (whether it’s natural airflow or fan-driven).

Why it matters: Wrong airflow design means heat won’t be removed efficiently.

Best tip: Align fins to airflow—vertical fins with wider gaps for natural airflow, and denser, horizontal fins for fan-driven (forced) airflow.

Choosing a Heat Sink by Size Alone

Mistake: Picking a heat sink just because it looks big, without checking if it cools well enough.

Why it matters: Bigger doesn’t always mean better if it doesn’t meet the cooling needs.

Best tip: Make sure the heat sink matches the required thermal resistance, considering material, fin design, and airflow.

Skipping Safety Margins

Mistake: Designing with no buffer, running parts right at their maximum temperature limits.

Why it matters: This can cause parts to fail sooner than expected.

Best tip: Choose heat sinks that keep parts cooler than their maximum rated temperatures to increase reliability and lifespan.

By avoiding these mistakes, you’ll design heat sinks that work better and keep your electronics safer and longer-lasting.